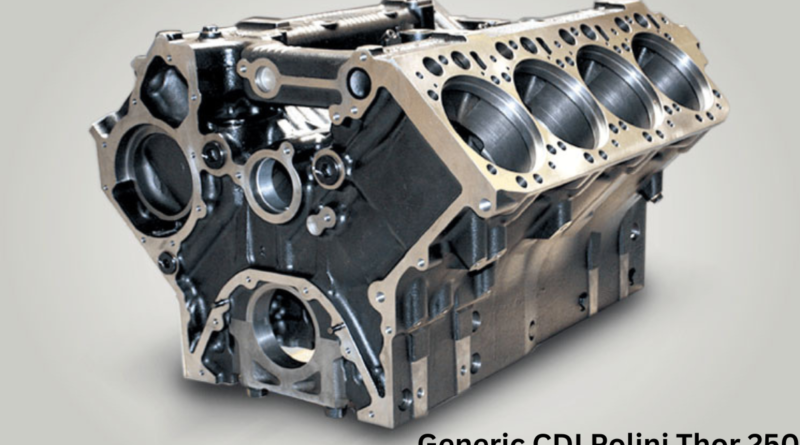

The Generic CDI Polini Thor 250 Engines: A Comprehensive Analysis

Introduction

Popular among paramotor pilots, the Polini Thor 250 is well-known for its effective performance and lightweight construction. The Capacitor Discharge Ignition (CDI) system, which is essential to the engine’s ignition process, is at the core of its dependable operation. This technique not only increases dependability but also adds to the paramotor’s overall safety, Generic CDI Polini Thor 250. Pilots must comprehend the features and operations of the CDI due to the demands of flying. The generic CDI used in the Polini Thor 250 will be examined in this article along with its features, functionality, typical problems, and maintenance advice to guarantee peak performance.

What is a Generic CDI Polini Thor 250 System?

In internal combustion engines, a CDI system is intended to supply a powerful spark to ignite the air-fuel mixture, Generic CDI Polini Thor 250. The Polini Thor 250’s generic CDI uses cutting-edge technology to improve power output and ignition timing. This technique allows the engine to respond more efficiently to throttle inputs, enabling a smoother acceleration during flight. The capacity to produce a dependable spark under diverse situations is vital for high-performance engines like the Thor 250. Because of its dual-spark capabilities, which guarantees steady ignition, it operates more smoothly and efficiently, particularly when performing crucial flight maneuvers.

Key Features

Capacitor Discharge Technology: This technology creates a strong spark for ignition by storing electrical energy in a capacitor and releasing it in a brief burst. Achieving maximum power requires optimum combustion efficiency, which is where this approach excels. Better performance at different altitudes and faster beginnings are also made possible by the rapid discharge.

Better Ignition Timing: Engine performance depends on precise timing. By improving torque and power, the generic CDI unit aids in ignition timing optimization. In addition to improving performance, this timing accuracy reduces engine stress and may even increase engine longevity. The CDI considerably lowers the chance of engine knocking by making sure that the ignition happens at the ideal time.

Lightweight Design: The Thor 250 engine’s overall lightweight design, which is essential for paramotor applications, is facilitated by the CDI unit’s low size. Weight loss improves maneuverability and fuel efficiency, two critical aspects for pilots on long flights. Additionally, a lightweight CDI improves handling and stability in the air by adding to the aircraft’s overall balance.

Reliability and Efficiency: Pilots can anticipate reliable operation, lower fuel consumption, and fewer no-spark situations with a well-designed ignition system. For pilots to be able to rely on their equipment while flying, especially under trying circumstances, this dependability is essential. Over time, an effective CDI unit also helps to keep the engine running at its ideal temperature, increasing its dependability.

Also Read: How Fast Do NASCAR Cars Go: The High-Speed 160mph World of NASCAR

Typical Problems and Solutions

Pilots should be aware that the CDI system may have certain issues despite its benefits. By being aware of these problems, you can lessen your irritation and save important flying time.

No-Spark Condition: A broken CDI unit may be the cause if the engine won’t start. It is crucial to do routine inspections on the spark plug and ignition coil. Furthermore, making sure the battery is completely charged might help avoid misconceptions regarding how the CDI works.

Timing Issues: Performance issues may arise from improper ignition timing. During installation, make sure the CDI is calibrated accurately. Even small changes can have a big impact, therefore pilots should consult the manufacturer’s specs to make sure the timing matches ideal performance requirements.

Wear and Tear: The CDI unit may experience wear over time, just like any other engine component. Regular inspections and maintenance can extend its lifespan. Maintaining a maintenance log can help track the CDI’s performance over time, making it easier to identify potential issues before they become critical. Overheating: High operating temperatures can affect the CDI’s efficiency. Adequate cooling and heat dissipation measures should be in place. Using heat-resistant materials in the installation area can further protect the CDI and other critical components from thermal damage.

Tips for Maintenance

To maintain the Polini Thor 250’s generic CDI operating at its best, adhere to these maintenance recommendations:

Frequent Inspections: Look for wear or damage, especially in the spark plug and ignition coil. It is possible to avoid unplanned malfunctions during flight by taking the time to check the wiring harness for frays or loose connections. Before every flight, a comprehensive examination can guarantee that every part is operating as intended.

Maintain Clean Connections: To avoid misfires or power outages, make sure all electrical connections are safe and clean. Using dielectric grease can help keep connections clean because corrosion can accumulate over time. Overall electrical efficiency can also be increased by routinely cleaning the connectors.

Track Temperature: Keep an eye on the engine’s running temperature. Examine and fix any possible causes if it runs hot all the time. Overheating problems can be avoided by putting extra cooling measures in place, like better airflow around the engine. Monitoring temperature can also assist in determining whether other elements, like as the CDI, are not functioning as well.

Replace Worn Parts: The CDI unit or associated parts may need to be replaced if problems occur, such as frequent no-spark situations. Maintaining a stock of replacement parts might help you minimize downtime and be ready for unforeseen malfunctions. Always select premium parts that fulfill or beyond OEM requirements when replacing components.

Conclusion

The Polini Thor 250’s generic CDI is a crucial part that has a big impact on the engine’s dependability and performance, Generic CDI Polini Thor 250. Pilots can improve their flying experience by making educated judgments based on their knowledge of its features, typical problems, and maintenance requirements. Timely interventions and routine maintenance can stop minor problems from becoming bigger ones. Every flight can be made safe and pleasurable with the CDI’s assistance in ensuring optimal power output and consistent ignition. Pilots will eventually have a more reliable and thrilling flying experience if they prioritize their CDI maintenance.

FAQs

What does CDI stand for?

CDI stands for Capacitor Discharge Ignition, a type of ignition system that delivers a high-voltage spark to ignite the fuel mixture in an engine. This technology is widely used in various internal combustion engines due to its effectiveness in providing reliable ignition, Generic CDI Polini Thor 250.

How can I tell if my CDI is failing, Generic CDI Polini Thor 250?

Common signs include a no-spark condition, rough engine performance, or difficulty starting the engine. If you experience these issues, inspect the CDI and related components. Seeking professional help can also provide insights into underlying problems that may not be immediately obvious, Generic CDI Polini Thor 250.

Can I replace my CDI with a generic unit, Generic CDI Polini Thor 250?

Yes, a generic CDI can be used as a replacement for the Polini Thor 250. Ensure that it is compatible with your engine model for optimal performance. Always check the specifications and reviews of the generic unit to ensure it meets your needs, Generic CDI Polini Thor 250.

How often should I maintain my CDI, Generic CDI Polini Thor 250?

Regular maintenance is recommended, particularly before each flying season. Inspect connections and components for wear, and replace any damaged parts promptly. Developing a routine maintenance schedule can help you stay ahead of potential issues, Generic CDI Polini Thor 250.

What is the impact of ignition timing on performance, Generic CDI Polini Thor 250?

Proper ignition timing is crucial for maximizing engine efficiency, power output, and overall performance. An incorrectly timed CDI can lead to reduced torque and increased fuel consumption. Understanding the optimal timing settings for your engine can help you achieve the best performance, Generic CDI Polini Thor 250.